UARPES end station

Figure 10. UARPES end station.

The end station consists of three chambers: loading, preparation, and analysis. The sample in the analysis chamber is located 28 m from the undulator. The area excitation by the monochromatic beam is 60 µm x 150 µm with the possibility of narrowing it down to a square of 60 µm x 60 µm through the exit slit.

In the analysis chamber, there is a five-axis cryogenic manipulator (3 translations and 2 rotation axes) with an open-flow cryostat, enabling the sample to be aligned in the axis of the electromagnetic optics of the analyzer and in the axis of the MCP-LEED diffractometer. During measurements, stable temperatures in the range of 6.5 - 500 K can be obtained by cooling with liquid helium or liquid nitrogen; higher and intermediate temperatures can be stabilized by a heater mounted on a cryostat and by the flow of a coolant. The manipulator is fully motorized and automated and communicates with the SES program.

In 2023, it is planned to install a new and modernized 6-axis manipulator for operation at extremely low temperatures (assumed 2.5 K under reduced pressure conditions and 4.25 K under normal conditions).

Figure 11. Station of a 5-axis cryogenic manipulator with a sample on a flag/omicron holder.

The base pressure at room temperature in the analysis chamber is <6×10-11 mbar (without the use of a cryogenic pump), which ensures a long lifetime during measurements even for reactive sample surfaces. For samples sensitive to hydrogen and residual UHV gases, it is possible and recommended to use a cryogenic pump; then the base pressure achieved is << 1 x 10-11 mbar.

For evaluation and analysis of the crystallographic quality and/or surface reconstruction of the samples, the MCP-LEED diffractometer (OCI Vacuum Microengineering Inc.) diffractometer is located in the analysis chamber.

The figure below shows the geometry of the ARPES measurements.

Figure 12. Measurement geometry. The angle between the axis of the detector and the beam of photons incident on the sample is 44°. The cryogenic manipulator has three Cartesian axes X, Y, Z and two rotary axes R1 providing azimuthal movement in the range of 350° and R3 ensuring tilt up to 135°. The orientation of the entrance slit and the polarization vectors of the radiation are marked.

The heart of the end station is the VG Scienta DA30L hemispherical photoelectron energy spectrometer, mounted in such a way that its input axis forms an angle of 44° with the photon beam. The analyzer is an HDA (Hemispherical Deflection Analyzer) multiplexing spectrometer capable of simultaneously recording about 106 points of the angular energy spectrum of electrons.

In the focal plane of the entrance lenses, there is a vertical entrance slit of the energy filter. Electrons entering the spectrometer at a given angle, i.e. also emitted from the sample at a given angle, are focused at one point on the focal plane by the entrance lens. As a consequence, the angular distribution of photoelectrons emitted from the sample towards the entrance slit is mapped on the focal plane. The electrons that pass through the slit further into the hemispherical filter region are then dispersed due to their energies, while keeping the ordering of the electrons due to entry angles. Behind the energy and angle filters is a highly sensitive 2D positional detector that records the electron current distribution on the plane. Then, the electron distribution is transformed from the detector plane to the space of angles and energies.

The DA30L detector is equipped with a system of deflectors in the area of the entrance lenses that allows to shift the angular distribution of photoelectrons mapped on the focal plane in the horizontal direction (perpendicular to the direction of the entrance slit). As a consequence, various sectors of the angular distribution that are not included in the spectrometer axis can be selected for energy analysis. For a stationary sample, the spectrometer can measure electrons whose directions fall within a 30° cone.

| Parameter | Value |

|---|---|

| Detector type | DA30L, MPC 2D |

| Detector modes | Deflection (3D), ARPES, XPS, UPS |

| Angular mods | ±7°, ± 15° |

| Entrance slits | 0.1 – 2.5 mm |

| Energy resolution | 1.8 meV |

| Angular resolution | 0.1° |

| EPass energy [eV] | 2; 5; 10; 20; 50; 100; 200 |

| Energy chanels | 1000 |

| Angular chanels | 750 |

The DA30L spectrometer allows you to measure three-dimensional maps of the photocurrent I(φ,θ,E), which then, using the software available on the beamline, can be transformed to momentum and energy space, obtaining the representation of the band structure.

An important advantage of using the deflection mode, which replaces the rotation of the sample, is the quick mapping in three dimensions (φ, θ and E) that does not require changes in the position (tilt), which eliminates the variability geometrical components in the transition matrix elements; the elimination of the risk of changing the excitation area on the sample during rotation (it is huge important for small samples and small size of the radiation beam), and elimination of the change of the geometry during the, e.g. of the dichroism measurements.

The DA-30L spectrometer has 9 entrance slits with a width from 0.1 mm to 2.5 mm. The angular resolution is better than 0.1° (in two directions), which corresponds to a k wave vector resolution from 0.002 to 0.01 Å-1, and the detector’s maximum energy resolution is 1.8 meV. The pass energy can be changed from 1 to 200 eV. The spectrometer operates in two angular modes ±7°, ±15° (corresponding to acceptance cones of 14° and 30°). The charge-coupled device (CCD camera positioned behind the MCP signal amplifier with a diameter of 40 mm) observes 1000 angular channels and 1064 energy channels simultaneously

3D VLEED spin filters

In the second half of 2023, the end station will be equipped with a 3D VLEED Ferrum spin-filter system with transfer optics by Scienta-Omicron.

Figure 13. Spin filters geometry.

More info coming soon.

Total resolution

Figure 14. Fitting the convolution of the Fermi and Gaussian functions to the Fermi step measured on polycrystalline gold at 8 K for 20 eV energy in PGM mode. The obtained FWHM value of the Gaussian function determines the total resolution of the beamline and the end station at 8 K temperature (4kT=2.8 meV). The pass energy was 2 eV, which gives a guaranteed resolution of 1.8 meV, the detector entrance slit was 200 (0.2 mm), and the beamline exit slit gap was 25 µm.

Automation

The URANOS beamline is largely motorized and automated. During the measurements, the user uses the SES software from Scienta-Omicron, which is communicated with the beamline software (Energy Configurator) and the end station (Manipulator). The measurement process is considerably automated, and the beamline control system is simplified and centralized. Therefore, remote measurements of samples that do not require specialized preparation are possible.

The Energy Configurator is a program that allows to control the beamline: opening and closing the shutters, setting the energy, light polarization or the gap of the exit slit. During the change energy of photonbeam, the undulator gap changes automatically for a given polarization. The PID (proportional-integral-derivative) controller minimizes the current difference measured at the horizontal right and left exit slits by changing the position of the focusing mirror in order to automatic location and centering of the photonbeam.

The energy configurator is connected with the SES data acquisition program and consequently enables automatic control of the excitation energy set from the SES program.

Figure 15. Energy configurator panel that allows setting the energy of the photons, polarization, gap of exit slits, and cff optimization. The program automatically selects other beamline parameters.

Samples preparation

The analytical chamber is connected to the preparation chamber, where the base pressure is 1×10-10 mbar. In this system, samples can be prepared in situ by various methods: e.g. by bombarding its surface with argon ions, heating up to 2000 K or cooling to 100 K, deposition of epitaxial layers, surface reactions in the gas phase, or another after beamline staff approval. In the preparation chamber, there are 3 ports for quick connecting of user devices such as effusion cells, EBV, cracker, etc. without losing the ultra-high vacuum in the chamber. There is also a port where a vacuum suitcase can be installed. The sample preparation process can be monitored using a LEED diffractometer with Auger spectroscopy, a residual gas analyzer (RGA), and quartz microbalance. Crystalline samples can be cleaved immediately prior to measurement in ultrahigh vacuum at room temperature or cryogenic temperatures. Soft thin films or van der Waals materials can be exfoliated under vacuum in the load lock chamber.

In the preparation chamber, there is also a source of AMD (Ce, K, Na, Ru, Li)

Up to 6 sample holders can be loaded into the loading chamber at the same time.

All elements used for mounting the samples have to be nonmagnetic, e.g. from pure metals such as Mo, Ta, Ti, or Cu. The samples should be mounted on omicron or flag type holders complying with the following parameters:

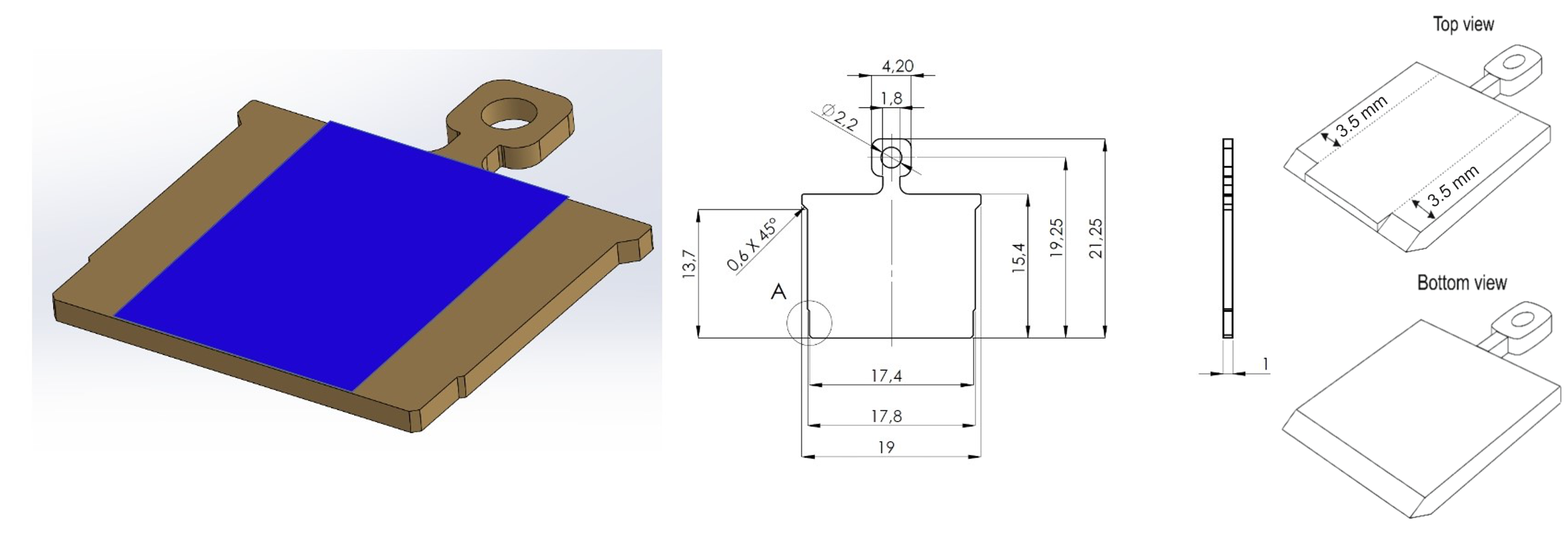

Figure 16. Sample holders

The blue area is the sample area. Required margins of 3.5 mm on each side.

To heat samples in the direct (electron beam) mode, the following holders should be used:

Figure 17. Sample holders to heat.